How to Rent Guide 2023 PDF: A Comprehensive Plan

The 2023 “How to Rent” guide, a crucial 18-page PDF, details tenant rights and responsibilities in England, alongside resources like Shelter and Citizen’s Advice.

Understanding the “How to Rent” Guide

The “How to Rent” guide, available as a PDF, is a fundamental resource for anyone navigating the private rental sector in England. Published by the government, this 18-page document provides a comprehensive overview of the renting process, from initial searches to ending a tenancy. It’s designed to empower tenants with knowledge of their rights and responsibilities, ensuring a smoother and more informed rental experience.

Beyond outlining legal obligations, the guide also covers practical aspects like tenancy agreements, deposit protection schemes, and how to address repairs or disputes. Several related resources, such as “Renting A Home: A Guide for Tenants” (48 pages), complement the core document, offering further detailed information. Understanding this guide is the first step towards a secure and successful tenancy.

What is the “How to Rent” Guide?

The “How to Rent” guide is an official government publication, released in PDF format, designed to educate prospective and current tenants in England about the rental process. This 18-page document serves as a key reference point, detailing the legal framework surrounding private renting. It’s more than just a checklist; it’s a comprehensive explanation of tenant rights, landlord obligations, and the procedures involved in establishing and maintaining a tenancy.

The guide aims to promote a fairer and more transparent rental market. It’s frequently updated to reflect changes in legislation, ensuring renters have access to the most current information. Resources like the FTR66 Renting Guide and broader private housing booklets supplement this core document, providing additional support and clarity.

Purpose of the 2023 Guide

The primary purpose of the 2023 “How to Rent” guide is to empower tenants with the knowledge necessary to navigate the rental process confidently and securely. This 18-page PDF clarifies rights and responsibilities, fostering a better understanding between tenants and landlords. It aims to prevent disputes by outlining legal requirements and best practices.

The guide also ensures landlords adhere to their legal obligations, promoting a compliant and ethical rental sector. By providing clear information on deposit protection, tenancy agreements, and repair procedures, it contributes to a more stable and transparent housing market. Ultimately, the guide seeks to improve the overall renting experience for everyone involved.

Where to Find the Official PDF

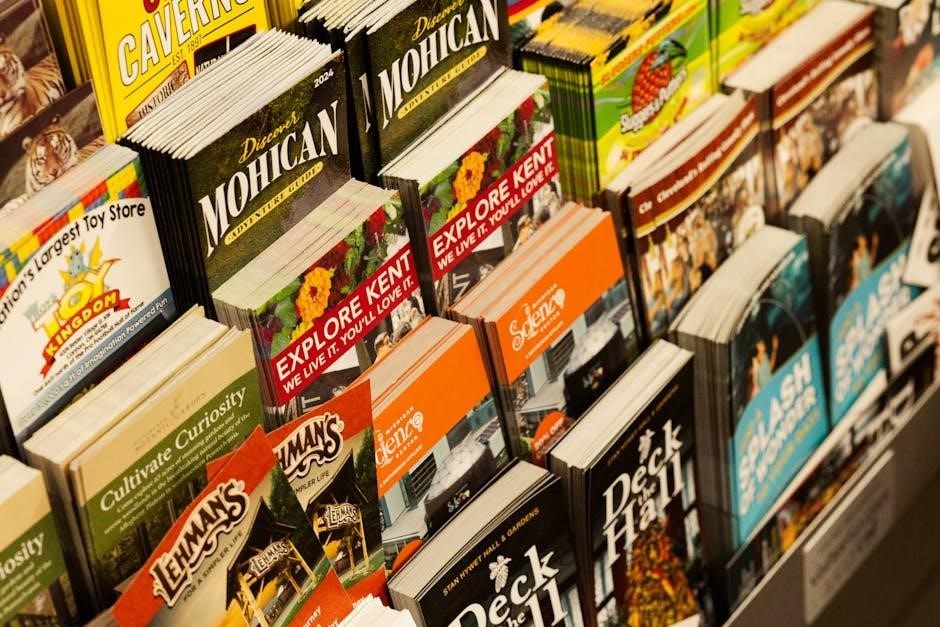

The official “How to Rent” guide 2023 PDF is readily accessible through official government sources to ensure tenants receive accurate and up-to-date information. A primary location is the UK government website, specifically the section dedicated to housing and renting. Direct links are often provided by organizations like Shelter and Citizen’s Advice Bureau, ensuring easy access for renters.

It’s crucial to download the guide only from these trusted sources to avoid outdated or misleading versions. Searching directly for “How to Rent Guide 2023 PDF” will yield results, but verifying the website’s legitimacy is paramount. Always prioritize official government domains for the most reliable information regarding your tenancy rights.

Downloading the Guide – Official Government Sources

To download the “How to Rent” Guide 2023 PDF, navigate to the UK government website. Look for the section pertaining to housing, renting, or tenant rights – a direct search within the site is recommended. The PDF is typically available for free download in a standard PDF format, easily opened with Adobe Reader or similar software.

Ensure your download originates from a “.gov.uk” domain to guarantee authenticity and avoid potentially harmful files. The 18-page document is a valuable resource, and official sources prioritize accessibility. Downloading from trusted platforms like Shelter or Citizen’s Advice Bureau, which link directly to the government PDF, is also a safe and reliable method.

Key Sections of the “How to Rent” Guide

The “How to Rent” Guide 2023 PDF comprehensively covers essential aspects of the rental process. Key sections begin with preparation for your property search, outlining what to consider before committing. It then details various tenancy types, explaining the nuances of each agreement.

A significant portion focuses on tenant rights, specifically deposit protection schemes and landlord responsibilities. The guide thoroughly explains the tenancy agreement itself, including understanding clauses and potential negotiation points. It also addresses the application process, required documentation, and common checks like credit referencing. This 18-page document is a vital resource for both new and experienced renters.

Before You Start Your Search

The “How to Rent” Guide 2023 PDF emphasizes thorough preparation before beginning your property hunt. Consider your budget realistically, factoring in not just rent but also bills and potential moving costs. Determine your desired location, prioritizing proximity to work, schools, or transport links.

Clearly define your needs and wants in a property, such as the number of bedrooms, garden access, or pet-friendliness. Understanding these preferences will streamline your search. The guide suggests researching local areas and average rental prices to set realistic expectations. Being prepared will save time and reduce stress during the process.

Types of Tenancies Explained

The 2023 “How to Rent” guide PDF clearly outlines the different types of tenancies available in England. Primarily, it details Assured Shorthold Tenancies (ASTs), the most common form, offering landlords specific grounds for possession.

The guide also explains Fixed-Term tenancies, lasting a pre-agreed period, and Periodic tenancies, rolling on a monthly basis after the fixed term ends. Understanding the nuances of each is crucial. It highlights the implications of each tenancy type regarding notice periods and tenant rights. Knowing your tenancy type empowers you to navigate your rental agreement effectively and understand your legal standing.

Your Rights as a Tenant

The 2023 “How to Rent” guide PDF comprehensively details your fundamental rights as a tenant in England. These rights encompass safe and habitable living conditions, protection from unfair eviction, and the right to live without harassment.

Crucially, the guide emphasizes your right to a written tenancy agreement, outlining all terms and conditions. It also details your entitlement to a property that is fit for purpose, meaning it’s structurally sound and free from serious hazards. Furthermore, the guide directs renters to resources like Shelter and Citizen’s Advice for further support and clarification on their legal entitlements.

Deposit Protection Schemes

The “How to Rent” guide 2023 PDF strongly emphasizes the legal requirement for landlords to protect tenants’ deposits. Landlords must register the deposit with a government-approved scheme within 30 days of receiving it.

These schemes – Deposit Protection Service (DPS), MyDeposits, and Tenancy Deposit Scheme (TDS) – resolve disputes fairly. The guide details how these schemes work, outlining the process for claiming your deposit back at the end of the tenancy. Failure to protect a deposit can result in penalties for the landlord, potentially including having to pay the tenant up to three times the deposit amount.

Landlord Responsibilities

The 2023 “How to Rent” guide PDF clearly outlines a landlord’s legal obligations to tenants. These include maintaining the property’s structure and exterior, ensuring gas and electrical safety with annual checks, and providing an Energy Performance Certificate (EPC).

Landlords are also responsible for fire safety, including ensuring smoke and carbon monoxide alarms are installed and working. The guide stresses the importance of responding promptly to reported repairs and respecting a tenant’s right to quiet enjoyment of the property. Failing to meet these responsibilities can lead to legal action and potential fines, as detailed within the document.

The Tenancy Agreement

The “How to Rent” guide 2023 PDF emphasizes the critical importance of a written tenancy agreement; This legally binding document details the rights and responsibilities of both the landlord and the tenant, covering rent amount, payment schedule, and deposit details.

The guide advises renters to carefully review all clauses and conditions before signing, paying particular attention to break clauses, restrictions on pets or alterations, and procedures for reporting repairs. Understanding the agreement is vital; tenants have the right to negotiate certain terms before committing, ensuring a clear and mutually acceptable arrangement is in place.

Understanding Clauses and Conditions

The 2023 “How to Rent” guide PDF stresses meticulous review of tenancy agreement clauses. Key areas include rent payment specifics, outlining accepted methods and late payment penalties. Break clauses, allowing early termination under specific conditions, require careful scrutiny.

The guide highlights clauses regarding property alterations, pet ownership, and subletting, noting potential restrictions. Understanding landlord access rights, repair responsibilities, and procedures for dispute resolution is crucial. Tenants should clarify ambiguous wording and seek legal advice if unsure about any condition, ensuring a comprehensive grasp of their contractual obligations before signing.

Negotiating Terms

The “How to Rent” guide 2023 PDF acknowledges tenant’s potential to negotiate certain tenancy terms. While rent is often fixed, discussing included amenities, garden maintenance responsibilities, or the timeframe for repairs can be fruitful.

Tenants can attempt to negotiate the deposit amount, ensuring it aligns with legal limits. Clarifying clauses regarding early termination or subletting is also possible. A polite, reasonable approach, backed by a clear understanding of tenant rights, increases negotiation success. Documenting all agreed-upon changes in writing, as an addendum to the tenancy agreement, is vital for future reference and dispute resolution.

The Rental Application Process

The 2023 “How to Rent” guide PDF outlines the typical rental application process. Landlords or letting agents usually require prospective tenants to complete an application form, providing personal and financial details.

Expect to furnish required documents, including proof of identity, income verification (payslips or employment contracts), and previous landlord references. Credit checks and referencing are standard practice, assessing your financial stability and rental history. Be prepared for potential guarantor requests if your credit history is limited. Honesty and transparency throughout the application are crucial for a smooth process, as misrepresentation can lead to rejection.

Required Documents

The “How to Rent” guide 2023 PDF emphasizes the documentation needed for a rental application. Typically, landlords require proof of identification, such as a passport or driving license;

Income verification is essential, usually in the form of recent payslips or an employment contract demonstrating stable earnings. Previous landlord references are also standard, allowing the landlord to assess your rental history and reliability. Bank statements might be requested to confirm financial stability. Be prepared to provide documentation relating to any dependents. Having these documents readily available streamlines the application process and demonstrates your preparedness as a tenant.

Credit Checks and Referencing

The 2023 “How to Rent” guide PDF highlights the importance of credit checks and referencing. Landlords and letting agents routinely conduct credit checks to assess your financial reliability and history of paying bills on time.

Referencing involves contacting previous landlords to verify your tenancy history – were you a responsible tenant? Did you pay rent promptly and maintain the property? A poor credit score or negative landlord references can hinder your application. Be prepared to explain any past credit issues. Consent is required before these checks are performed, ensuring data protection regulations are followed.

During Your Tenancy

The 2023 “How to Rent” guide PDF emphasizes tenant responsibilities and rights throughout the tenancy. Promptly reporting repairs is crucial; landlords are legally obligated to maintain the property’s structure and essential services. Keep a record of all communication regarding repairs.

Dealing with disputes requires clear communication with your landlord or letting agent. The guide advises documenting everything in writing. If issues escalate, mediation services can be helpful. Understanding your rights regarding access for inspections is also vital – landlords must provide reasonable notice. Maintaining a positive relationship through open communication is key to a smooth tenancy.

Reporting Repairs

The 2023 “How to Rent” guide PDF clearly outlines the process for reporting repairs. Tenants must inform their landlord or letting agent promptly about any necessary repairs, especially those affecting safety or habitability.

Documentation is key; keep a written record of all reported issues, including dates, descriptions, and communication methods. Landlords have a legal obligation to address repairs within a reasonable timeframe. The guide suggests following up if a response isn’t received. Emergency repairs – like a burst pipe – require immediate attention and should be reported urgently. Knowing your rights regarding repair timelines is essential for a comfortable tenancy.

Dealing with Disputes

The 2023 “How to Rent” guide PDF emphasizes clear communication as the first step in resolving disputes with landlords or letting agents. Attempting a direct, amicable discussion is often the most effective initial approach.

If direct communication fails, the guide recommends exploring mediation services. These offer a neutral third party to facilitate a resolution. For more serious issues, tenants can seek advice from organizations like Shelter or the Citizen’s Advice Bureau. Formal dispute resolution may involve pursuing legal action, but this should be considered a last resort. Documenting all communication and evidence is crucial throughout the process, as highlighted in the guide.

Ending Your Tenancy

The 2023 “How to Rent” guide PDF clearly outlines the procedures for legally ending a tenancy agreement. Understanding notice periods is paramount; these vary depending on the tenancy type and agreement terms. Tenants are generally required to provide written notice to their landlord, adhering to the specified timeframe.

The guide stresses the importance of a proper check-out process, including a detailed inventory assessment to avoid disputes over deposit deductions. Deposit returns must adhere to legal requirements, typically within ten days of the tenancy ending, with a clear breakdown of any deductions. Seeking advice from Shelter or Citizen’s Advice is recommended if issues arise regarding the deposit.

Notice Periods

The “How to Rent” guide 2023 PDF emphasizes that notice periods are critical when ending a tenancy. Generally, tenants needing to leave a periodic tenancy (rolling month-to-month) must provide at least one month’s notice. However, this can vary based on the rental agreement’s specific clauses.

For fixed-term tenancies, ending before the term concludes often requires landlord agreement or facing potential financial penalties. The guide details how landlords must also provide adequate notice if they wish to regain possession, adhering to legal minimums. Understanding these periods, as outlined in the PDF, prevents legal complications and ensures a smooth transition for both parties.

Deposit Returns

The 2023 “How to Rent” guide PDF thoroughly covers deposit returns, a frequent source of tenant-landlord disputes. It stresses that landlords must protect tenant deposits within a government-approved scheme within 30 days of receipt. These schemes – DPS, TDS, and MyDeposits – are crucial for resolving disagreements.

The guide details the process for requesting a return, emphasizing the need for a clear inventory check-in and check-out report. Landlords can only make deductions for legitimate reasons, like damage beyond fair wear and tear, or unpaid rent, and must provide detailed evidence. The PDF highlights dispute resolution services offered by the schemes if agreement isn’t reached.

Additional Resources for Renters

The 2023 “How to Rent” guide PDF directs renters to vital external support networks. Shelter provides expert advice on housing law, homelessness, and debt, offering a free helpline and online resources. Citizen’s Advice Bureau offers impartial guidance on a wide range of issues, including renting, benefits, and legal rights.

The guide also implicitly points towards tenancy deposit scheme dispute resolution services (DPS, TDS, MyDeposits) as resources. Furthermore, local councils often have housing advice teams. Accessing these resources is crucial for understanding your rights and navigating potential issues during a tenancy, supplementing the information within the PDF itself.

Shelter and Citizen’s Advice Bureau

Both Shelter and the Citizen’s Advice Bureau are invaluable resources for renters, frequently referenced alongside the “How to Rent” guide 2023 PDF. Shelter specializes in housing-related issues, offering detailed legal advice, practical support, and a helpline for those facing homelessness or unfair treatment.

Citizen’s Advice provides broader guidance, covering everything from tenancy agreements to benefit claims and dispute resolution. They offer free, impartial, and confidential advice, both in person and online. Utilizing both organizations ensures renters have comprehensive support, complementing the information provided within the official government PDF guide.

Renting in England vs. Other UK Nations

While the “How to Rent” guide 2023 PDF primarily focuses on regulations within England, it’s crucial to understand that rental laws differ across the UK. Scotland, Wales, and Northern Ireland each possess distinct legislation governing tenancies, deposit protection, and eviction processes.

Renters moving between these nations must familiarize themselves with the specific rules applicable to their new location. Resources like Shelter and Citizen’s Advice offer tailored guidance for each country. The English guide serves as a foundational understanding, but isn’t universally applicable, highlighting the need for localized legal advice.

Changes in Rental Legislation 2023

The 2023 “How to Rent” guide PDF reflects ongoing adjustments to rental legislation in England. While specific details require consulting the full document, key areas of change often involve updates to eviction notice periods, requirements for property condition reports, and regulations surrounding Right to Rent checks.

Landlords and tenants alike must stay informed about these evolving laws to ensure compliance and protect their rights. The guide serves as a vital resource for understanding these changes, but it’s advisable to supplement it with legal counsel or advice from organizations like Shelter for the most current interpretations.

Common Mistakes to Avoid When Renting

The 2023 “How to Rent” guide PDF highlights frequent errors renters make. These include failing to thoroughly inspect the property before signing a tenancy agreement, neglecting to document existing damage with photos or videos, and not fully understanding the terms of the tenancy contract – particularly clauses regarding repairs and rent increases.

Another common mistake is skipping deposit protection scheme registration. Renters should also avoid making verbal agreements without written confirmation and neglecting to obtain a copy of the Energy Performance Certificate (EPC). Proactive diligence, guided by the PDF, minimizes potential disputes and ensures a smoother rental experience.

Understanding Energy Performance Certificates (EPCs)

The “How to Rent” guide 2023 PDF emphasizes the importance of Energy Performance Certificates (EPCs). These certificates rate a property’s energy efficiency from A (most efficient) to G (least efficient). Landlords are legally required to provide an EPC to prospective tenants before a rental agreement is finalized.

Understanding the EPC rating helps renters estimate potential energy bills. A higher rating suggests lower costs. The guide advises renters to consider EPC ratings when comparing properties, as energy efficiency impacts both finances and environmental impact. Reviewing the EPC details allows informed decisions about long-term rental suitability.

The Role of Letting Agents

The 2023 “How to Rent” guide PDF acknowledges the significant role letting agents play in the rental process. These agents act as intermediaries between landlords and tenants, handling property viewings, referencing, and tenancy agreements.

The guide highlights the importance of verifying an agent’s credentials. Reputable agents should be members of a redress scheme, offering dispute resolution services. Renters should understand the agent’s fees and services provided. While agents can simplify the process, the guide stresses tenants’ rights and responsibilities remain paramount, regardless of agent involvement.

Using Online Rental Platforms

The “How to Rent” guide 2023 PDF doesn’t directly focus on online platforms, but acknowledges their growing prevalence in the rental market. Websites and apps offer extensive property listings, streamlining the search process for tenants.

However, the guide implicitly advises caution when using these platforms. Tenants should verify property details independently and be wary of scams. Always prioritize in-person viewings before committing to a tenancy. Understanding your rights, as outlined in the guide, is crucial even when finding properties online. Thoroughly review tenancy agreements and ensure the landlord or agent is legitimate before exchanging any funds.

Staying Safe While Renting

While the 2023 “How to Rent” guide PDF primarily focuses on legal aspects, tenant safety is implicitly addressed through responsible landlord obligations. Ensuring properties meet safety standards – gas, electrical, and fire – is a key responsibility detailed within.

Tenants should report any safety concerns immediately to their landlord or letting agent. The guide emphasizes the importance of a well-maintained property. Beyond this, personal safety is paramount. Be cautious when viewing properties, especially alone, and verify the identity of landlords and agents. Document all communication and maintain copies of important documents for your protection throughout the tenancy.